Technology

The proprietary technology of A-membranes is based on surface modifications of ceramic membranes. We can apply our surface modifications on commercially available ceramic membranes.

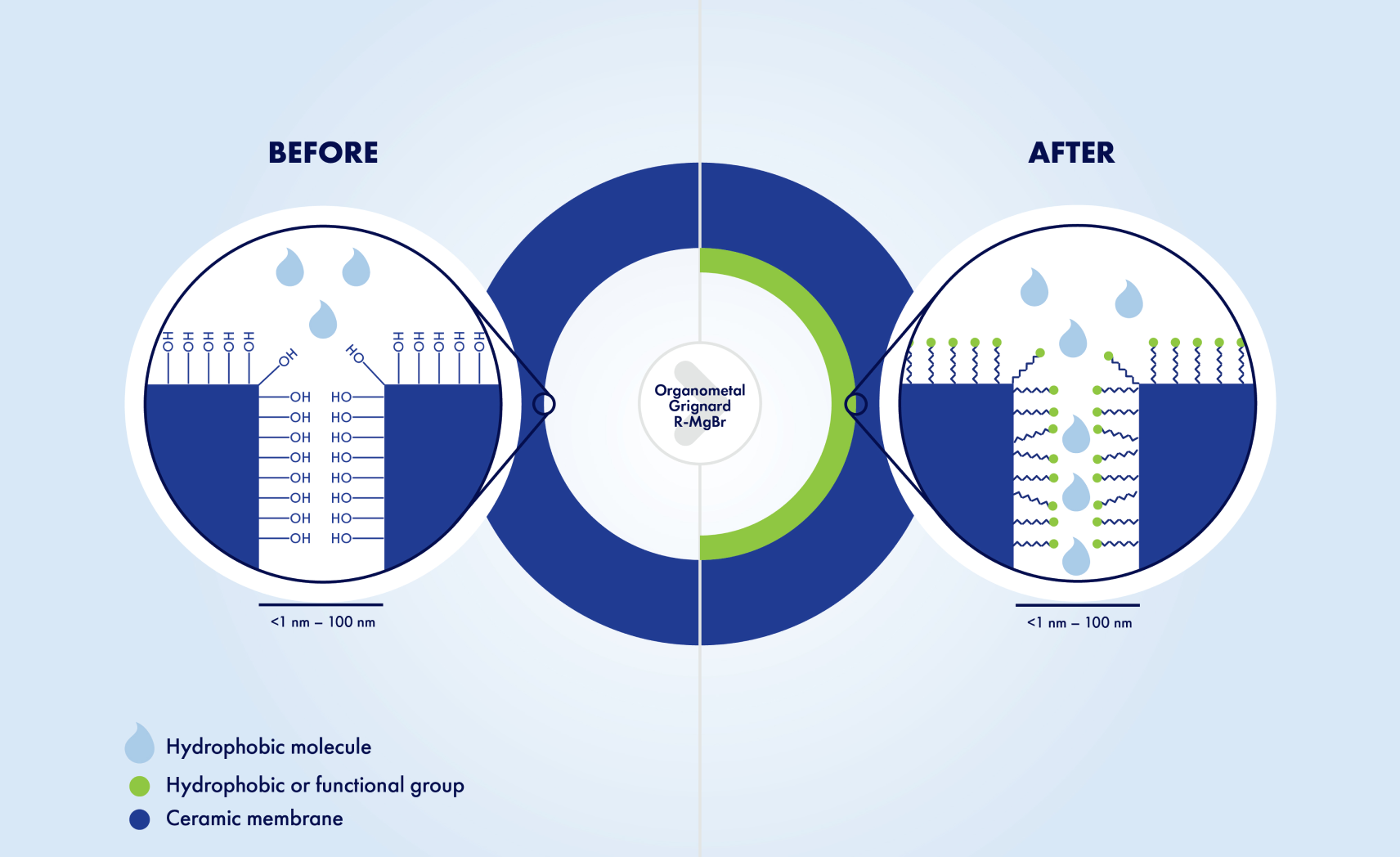

By means of “Grignard chemistry” we graft the active filtration layer of ceramic membranes with organic functionalities and create a direct “M-C”-bond between the metal of the ceramic material and the carbon of the organic function. The resulting A-membranes combine high stability and tailor-made affinity. This stability results from the robustness of the ceramic support on the one hand, and the stable ceramic-organic bond on the other hand. Other technologies to produce hybrid inorganic/ organic membranes, e.g. condensation reactions or coating techniques, do not yield this stable direct bond and are easily prone to rapid hydrolysis, thermal decomposition, or solvent attacks. A-membranes remain stable, without leaching, at high operating temperatures (150°C and above), in a large pH window (depending on the type of acid/base) and in solvents (a wide selection of polar, non-polar, aromatic, protic and aprotic solvents have been tested). A-membranes do not swell and can be heat-sterilized, stored dry after cleaning, do not need glues or spacers…

A-membranes’ grafting technology offers a very wide application window:

The grafting can be realised on a multitude of ceramic materials: most metal oxides and silicon carbides, with pore sizes ranging from micro- down to ultra- and nano-filtration. Furthermore, we can offer a complete library of organic moieties to be grafted to the membrane surface.

The organic groups we attach to the surface of the filtration layer of the membrane are altering the surface characteristics. While unmodified ceramic membranes are always strongly hydrophilic, grafting organic groups will shift this behaviour in a tunable manner towards more lipophilicity. The chosen grafting layer will exhibit bespoke interactions with the feed stream and attract wanted products and/or repel unwanted products. A-membranes adapts the interactions between membrane surface, solvent, and solute to the requirements of the customers’ process. This way they enable continuous separation of components that otherwise cannot be separated, and replace or intensify existing separation solutions (e.g. distillation, chromatography, coupling reaction-separation) for both solvent- and aqueous-based streams. As all membrane technologies, it is a sustainable technology, with reduced energy costs and a smaller environmental footprint.

The tunable affinity of the A-membranes allows for an improved performance in different applications, 3 examples:

As indicated above, our membranes have proven not to leach (= are not releasing impurities into the process) in difficult process circumstances. This behaviour is of particular interest to e.g. the pharmaceutical industries, biotech companies, food producers and other industries processes where purity is crucial. Till now, the purity has been assessed on an ad-hoc basis, but we are working towards an FDA (Food and Drug Administration) approval and a GMP certification that will facilitate the use of these types of membranes in the heart of pharmaceutical production processes. A-membranes are also safe for use in the food-industries and comply with directive 2005/31/EC.