Products & Services

Fill in this form to receive the required Data Sheets in your mailbox:

1

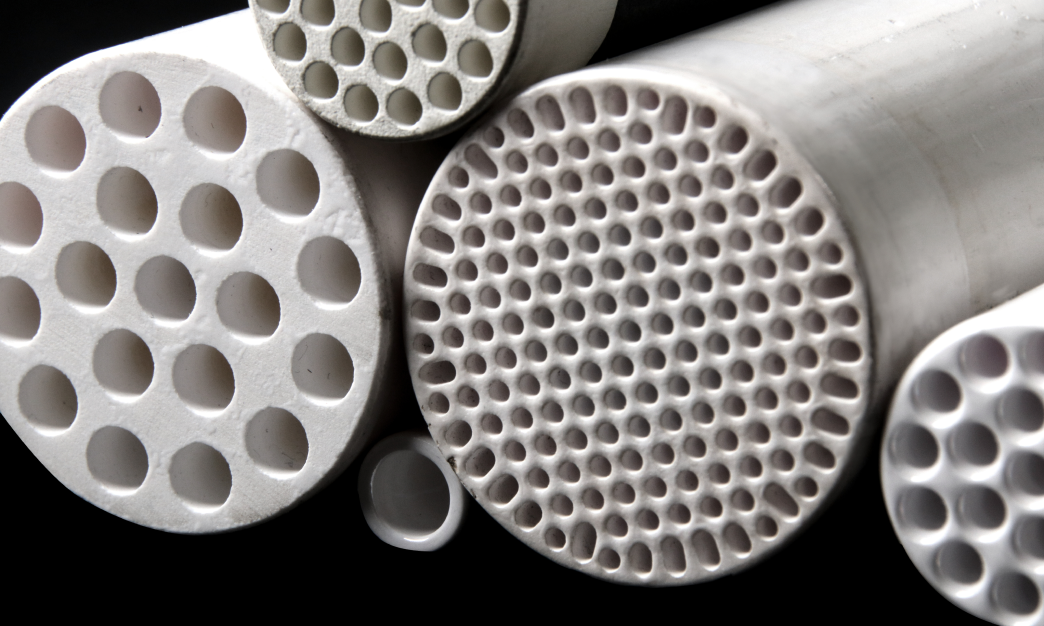

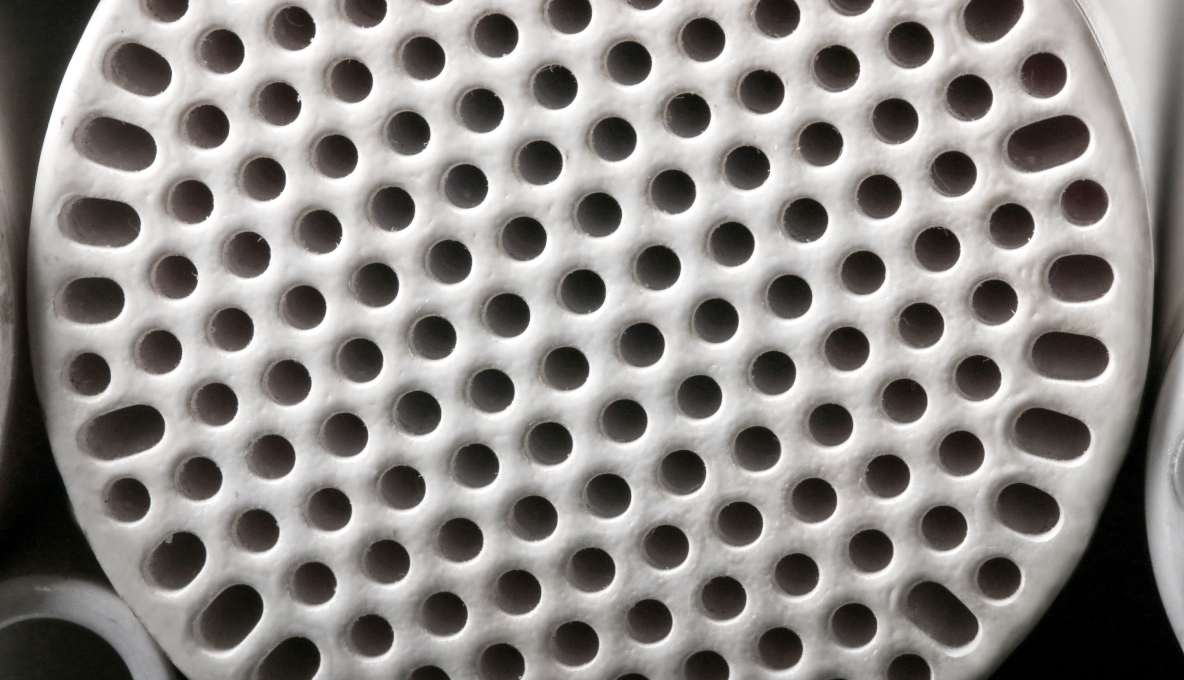

Grafted tubular ceramic membranes – available for industrial use and for R&D applications

Advantages

- Ceramic membranes with filtration layer made of metaloxides or SiC, and an organic layer grafted to the active surface layer

- Wide range of organic functionalisations available

- Non-leaching technology

- Resistant to high temperatures

- Excellent solvent stability

- Resistant to wide pH window

- Easily cleanable

- Dry storage possible after cleaning, without loss of performance

- No use of glues, spacers, fillers…

- Inert to microbiological degradation

- Steam sterilisable

Technical characteristics

- Tubular geometry, diameter ranging from 10 mm upwards – 25 and 41 mm being industrial standards; 10 mm lab-membrane standard

- Ceramic support with channel structure – channel diameter ranging from 2mm up to 15 mm depending on chosen geometry

- Available in micro-, ultra and nanofiltration ranges with pore size ranging from 1µm down to <1 nm, and MWCO ranging from 200 Da up to >100 kDa

- Length: 250 mm, 500 mm for lab-use and “industrial length” depending on the chosen membrane type: usually varies between 1000 mm and 1500 mm

Receive the Technical Data Sheet and / or request more information.

2

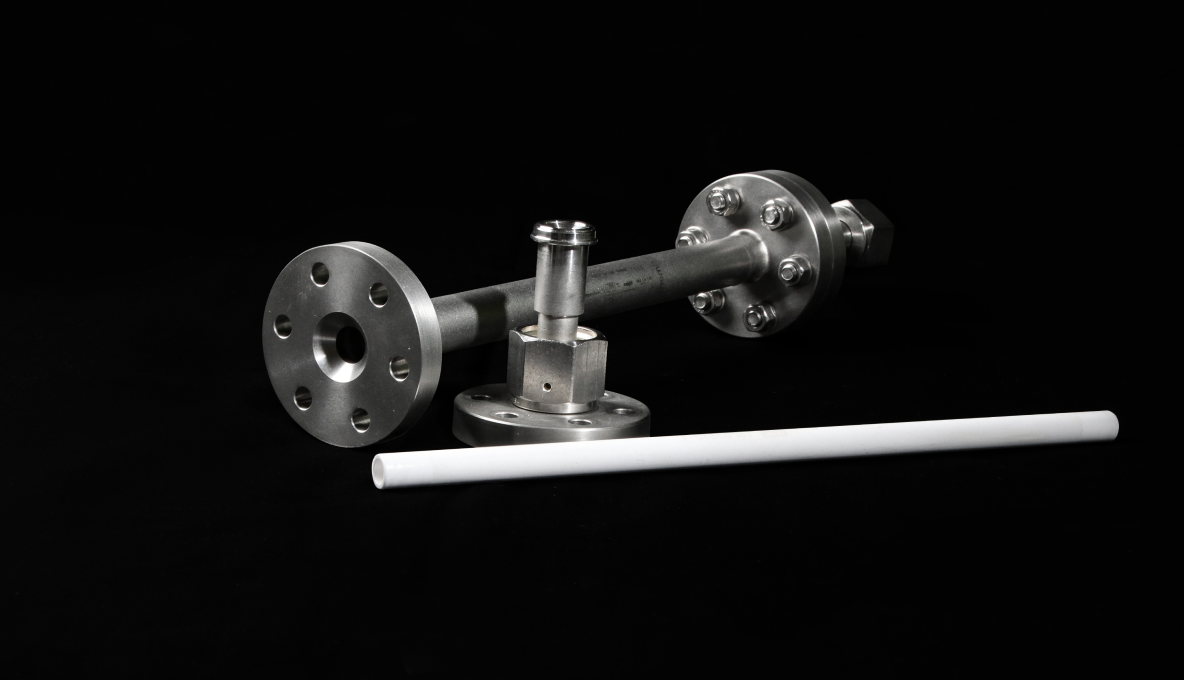

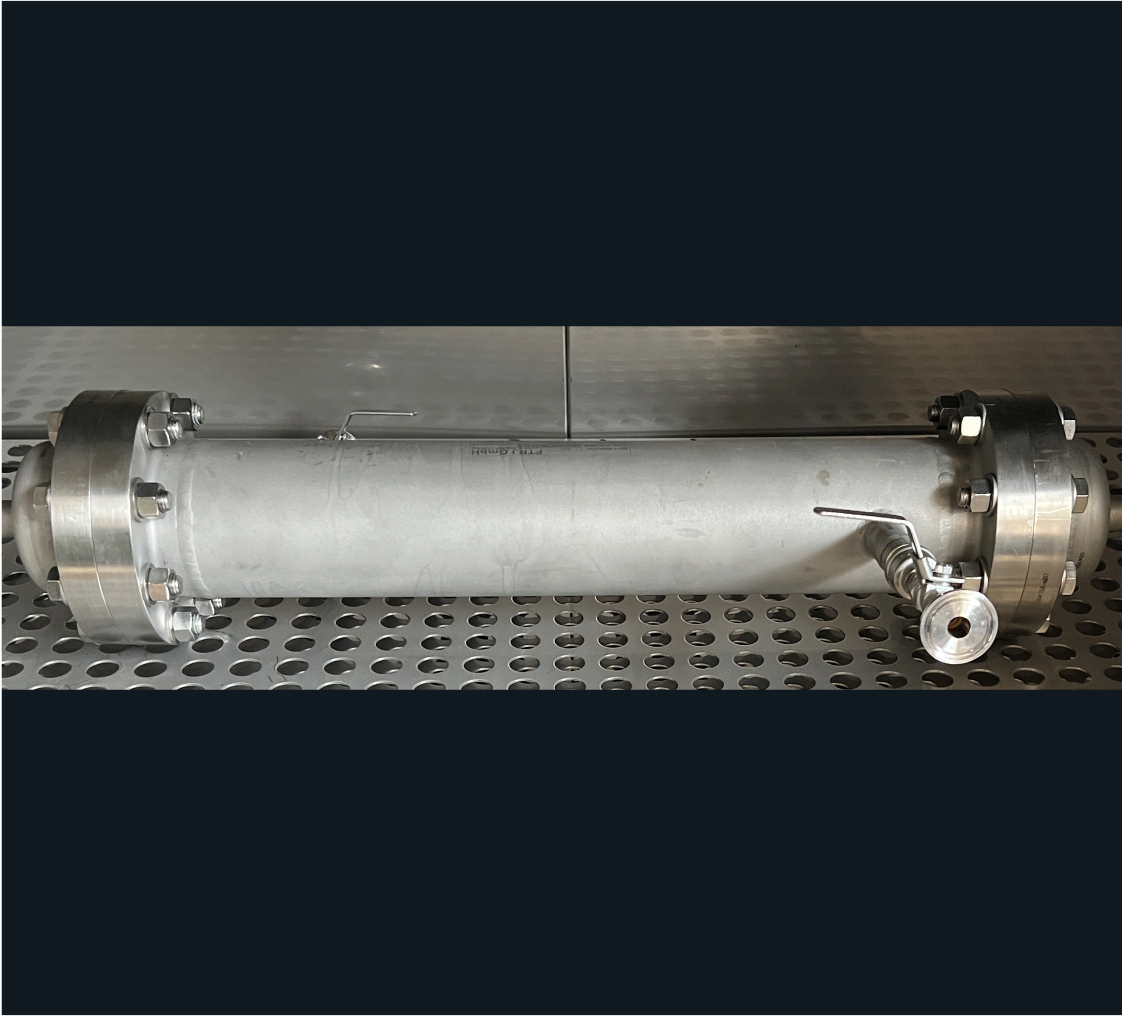

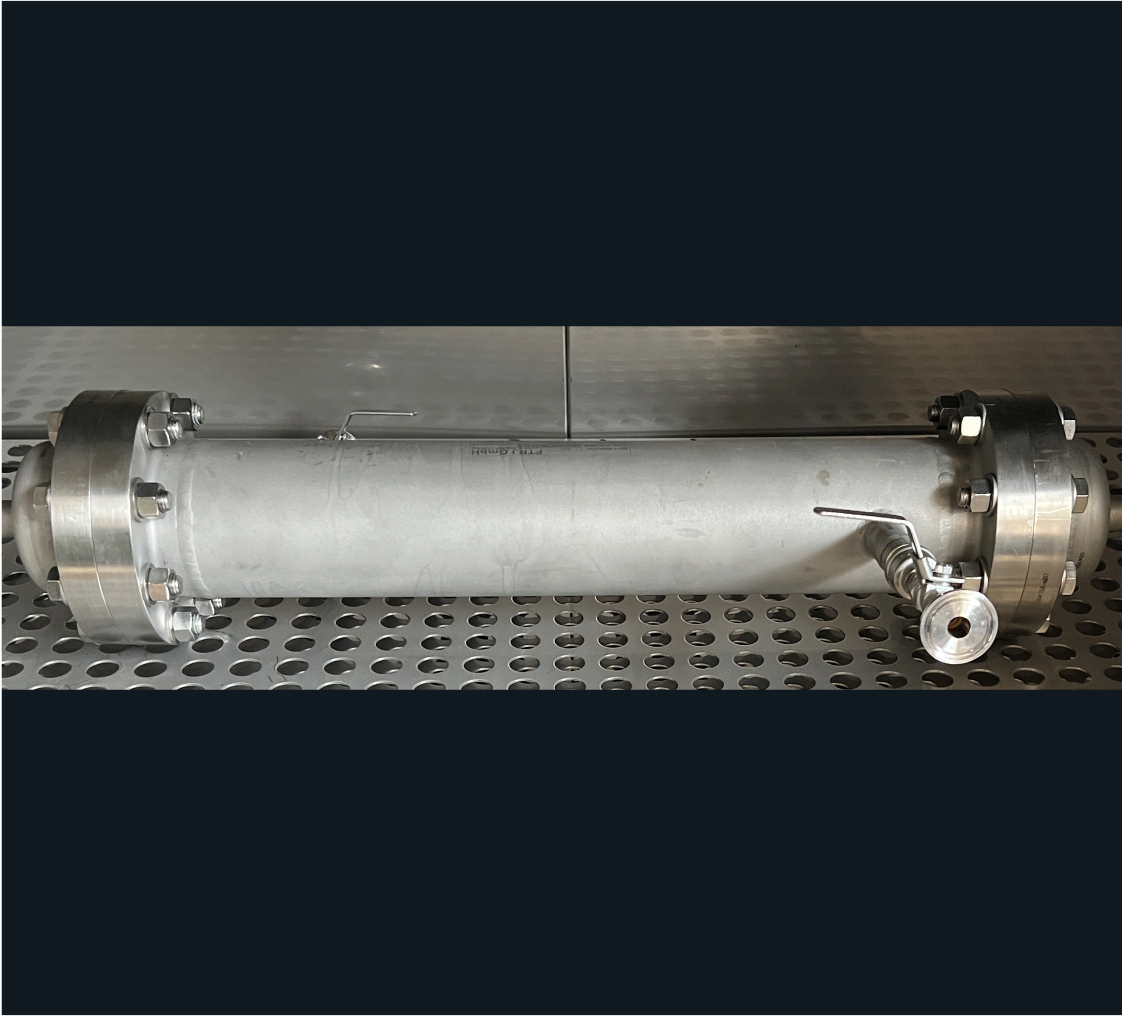

Membrane housings

- Membrane housings made of stainless steel for use with our tubular grafted ceramic membranes – pharmaceutical grade materials with certificates available

- Lab, pilot-scale, and industrial housings

- Length: 250 mm, 500 mm for lab-use and “industrial length” depending on the chosen membrane type: usually varies between 1000 mm and 1500 mm

- Membrane diameters ranging from 10 mm upwards

- Standardised housings available with filtration area up to and above 30 m²/housing, depending on the chosen membrane

- Flanged, tri-clamp or threaded connections

- Choice of gasket materials depending on process needs (EPDM, FKM, FFKM, …)

3

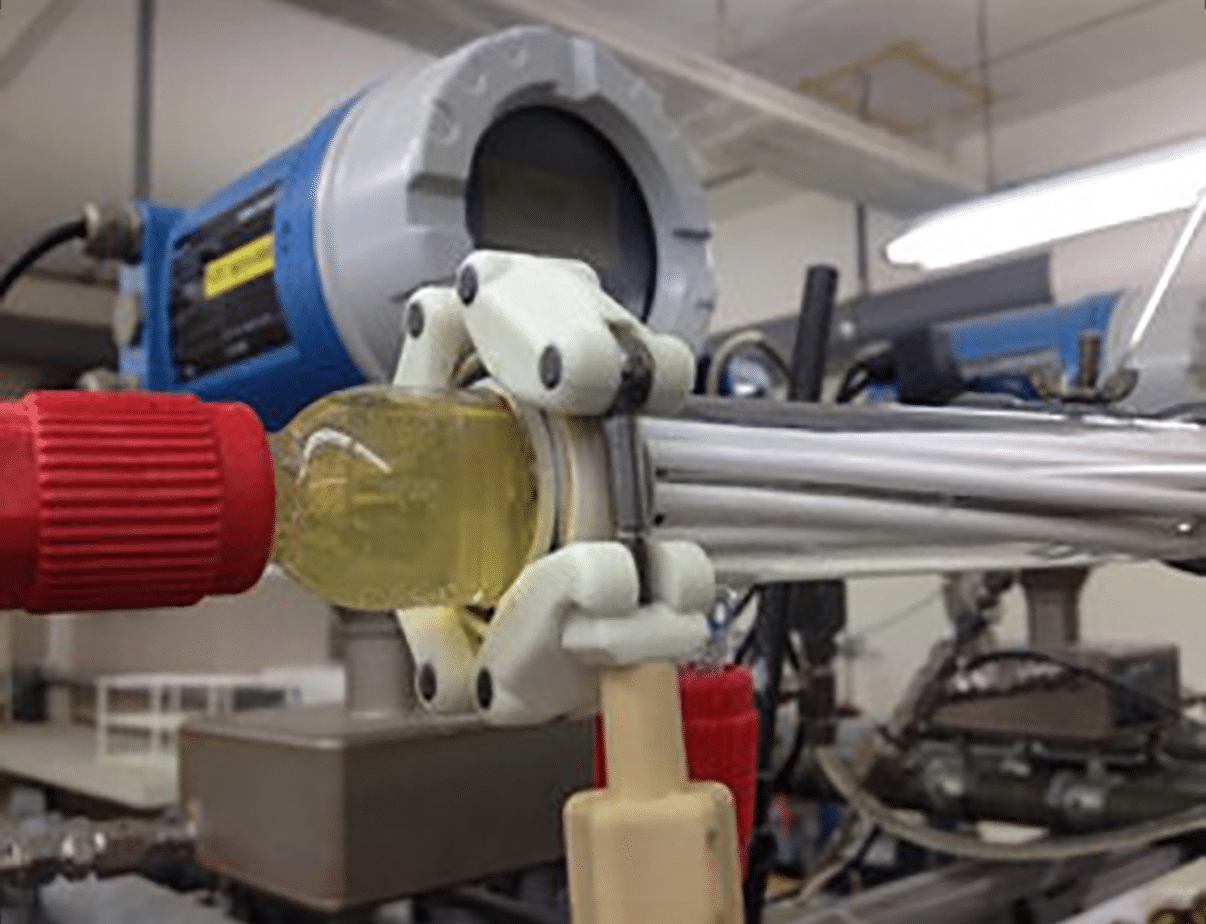

Membrane contactors for membrane extraction / gassing and degassing of fluids

Membrane extraction is a membrane-based separation technique that selectively transfers specific components, such as gases or solutes, from one fluid phase to another. This process relies on diffusion of the desired components from one liquid to the second. A key element in our know-how is the design of a process with maximalised diffusion rates.

Membrane contactors facilitate these membrane extraction processes. They allow contact of a liquid that penetrates the membrane with a second – non-penetrating- liquid without the two mixing. This intimate contact allows for selective mass transfer, enabling the extraction or separation of specific components.

Membrane contactors are utilized in various industries, including pharmaceuticals, fragrances, chemical processing, and environmental engineering.

Membrane contactors are also used for controlled gassing and degassing of liquid phases (e.g. of controlled gassing of bioreactors, degassing when the presence of oxygen or other gasses is decremental to product quality – e.g. when dealcoholizing beer).

The main benefit of membrane extraction is the prevention of emulsification of the two involved liquids. There is no need for long relaxation times. Furthermore, membrane extraction offers more freedom when choosing the appropriate extractant than with classical extraction techniques. In essence, membrane contactors offer a combination of selectivity, efficiency, and versatility, making them valuable tools in separation processes across different industries.

A-membranes offers membrane contactors based on different membrane technologies and chemistries. We offer small lab scale contactors, mid-scale contactors for piloting and large scale for industrial applications. Our company also offers complete turn-key installations for membrane extraction or membrane (de)gassing.

Receive the Technical Data Sheet and / or request more information.

4

Feasability studies

- In the lab, we assess the feasibility of a membrane filtration setup for your process needs

- We determine the right combination of ceramic material and the best fitting organic surface modification by grafting: tailoring the membrane to your specific process needs

- The goal is to design the future industrial process by determining the process parameters (flow rates, pressure, …)

- If required a first techno-economic evaluation can be included

- Usually, this type of study work is performed on 25 cm single channel or 50 cm multichannel membranes, but industrial format testing can be done in the lab as well

5

Pilot Testing and Pilot Installation Rental Service

- Scaling up from lab to full scale production can be quite a step. It is often necessary to detail the process parameters further, and to obtain confirmations on longer filtration runs. We offer intermediate scale testing – pilot testing – either in our lab or at your premisses.

- A-membranes can offer skid mounted, mobile pilot testing equipment for rent with different filtration capacities. We can offer installations for both aqueous streams and solvent-based streams (ATEX) in micro-, ultra and nanofiltration. We can also offer installation that comply with food or with GMP requirements.