Cases

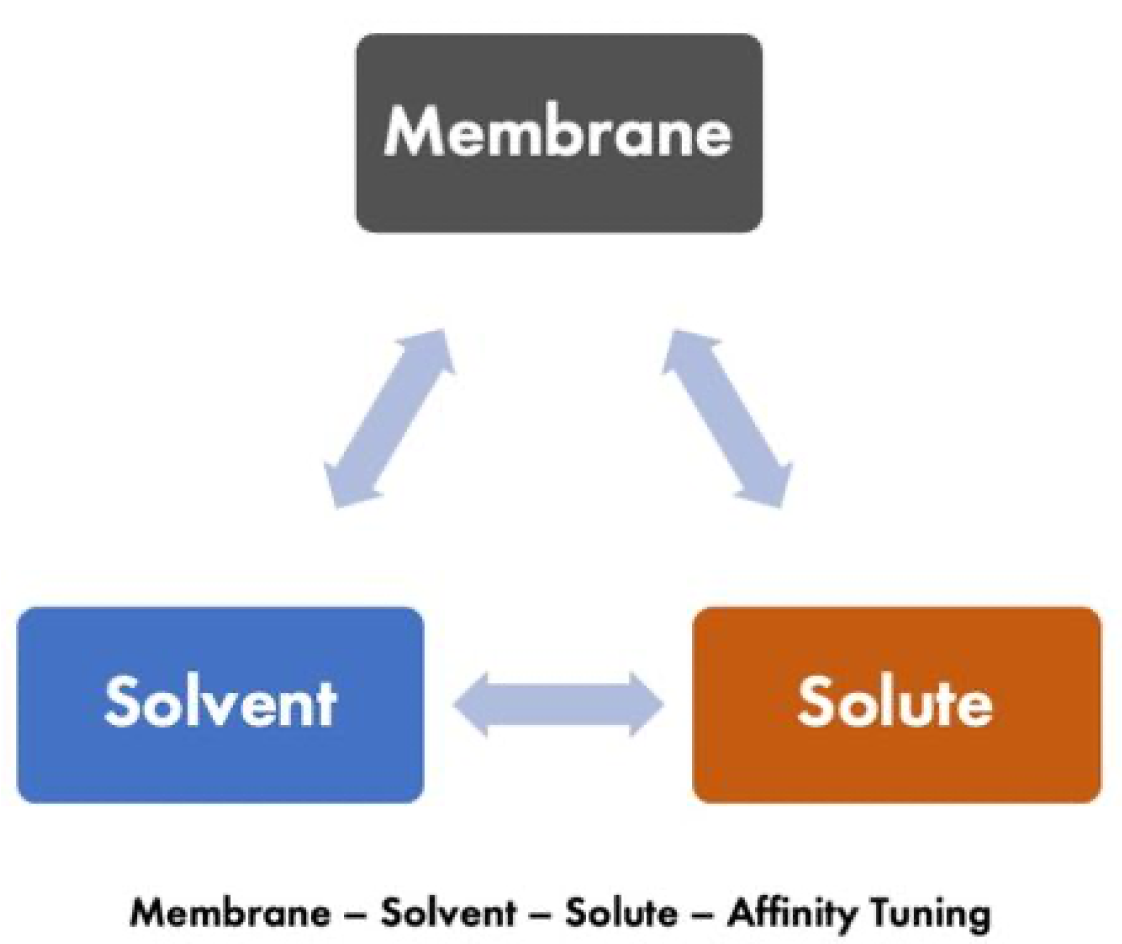

Tuning the membrane-solvent-solute affinity to the needs of the customers’ separation challenge leads to a performance increase. New separation processes become possible by membrane filtration and others become more efficient. A-membranes expand membrane filtration from a pure size-based separation process to an affinity-based separation process.

Tunable affinity separations

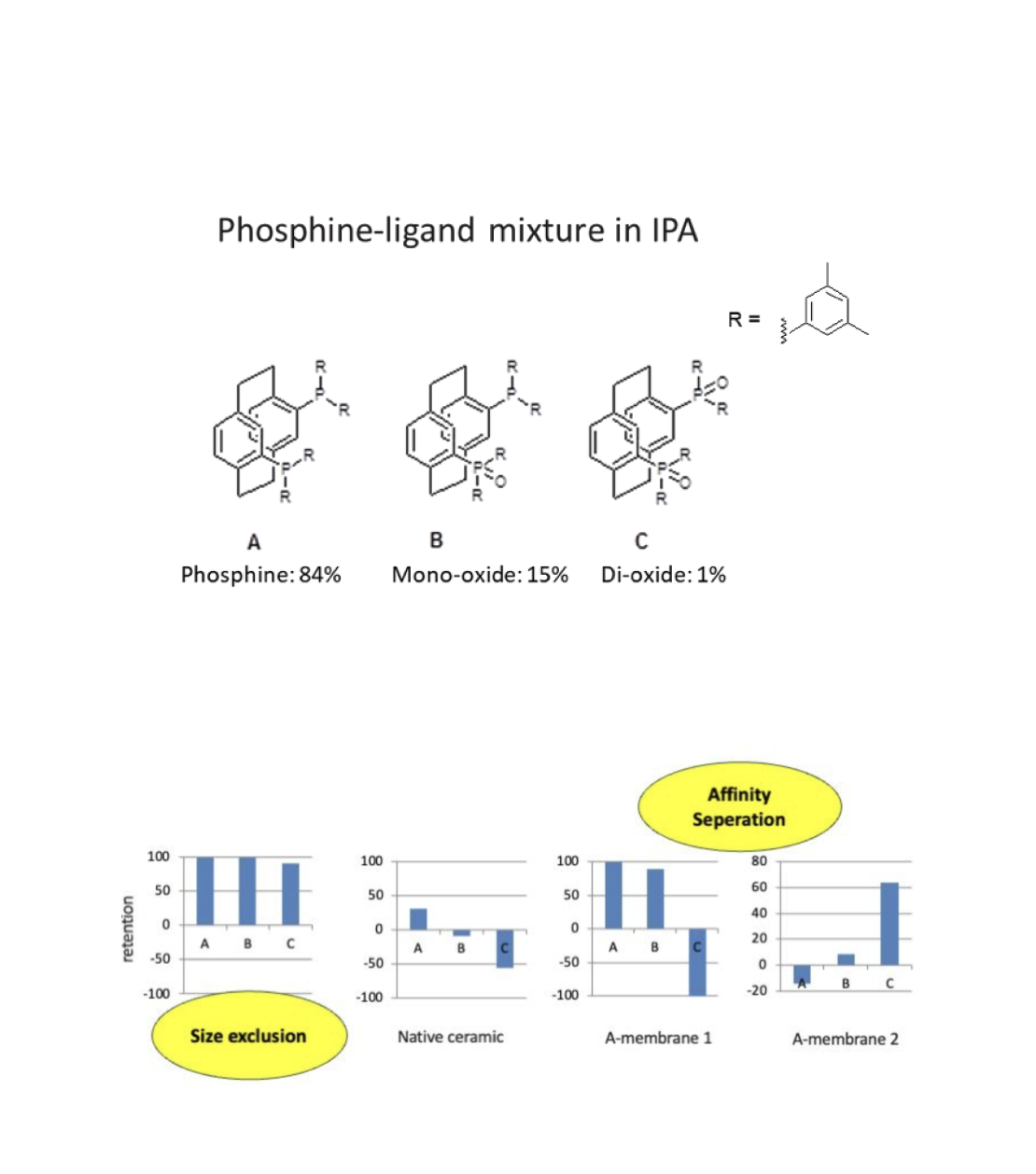

This industrially relevant example treats the separation of well-known phosphine ligands for homogenous transition metal catalysts, often used in fine chemistry. The preferred phospine ligand BINAP is not oxidised, but in contact with air the mono oxidised and di-oxidized versions are formed. All three phosphines have similar molecular sizes but their chemical affinity depends on the oxidation degree. When filtrating such a mixture in isopropanol (IPA) using different nanofiltration A-membranes, differences in retentions appear, not achievable with polymeric benchmark membranes. With one type of A-membranes, the dioxidised phosphine can be preferentially permeated through the membrane (negative retention), while BINAP and the mono-oxide are very well retained, allowing a clear separation. Changing the affinity of the A-membrane results in the opposite separation: phosphines BINAP and its mono-oxide pass through the membrane, while the dioxide is retained. This example demonstrates the wide flexibility that A-membranes has to offer: membrane performance can be tuned by tailoring the solute-membrane affinity, resulting in affinity-based separations like in chromatography.

Unlike chromatography, A-membrane separation is easily scalable, and continuous.