Cases

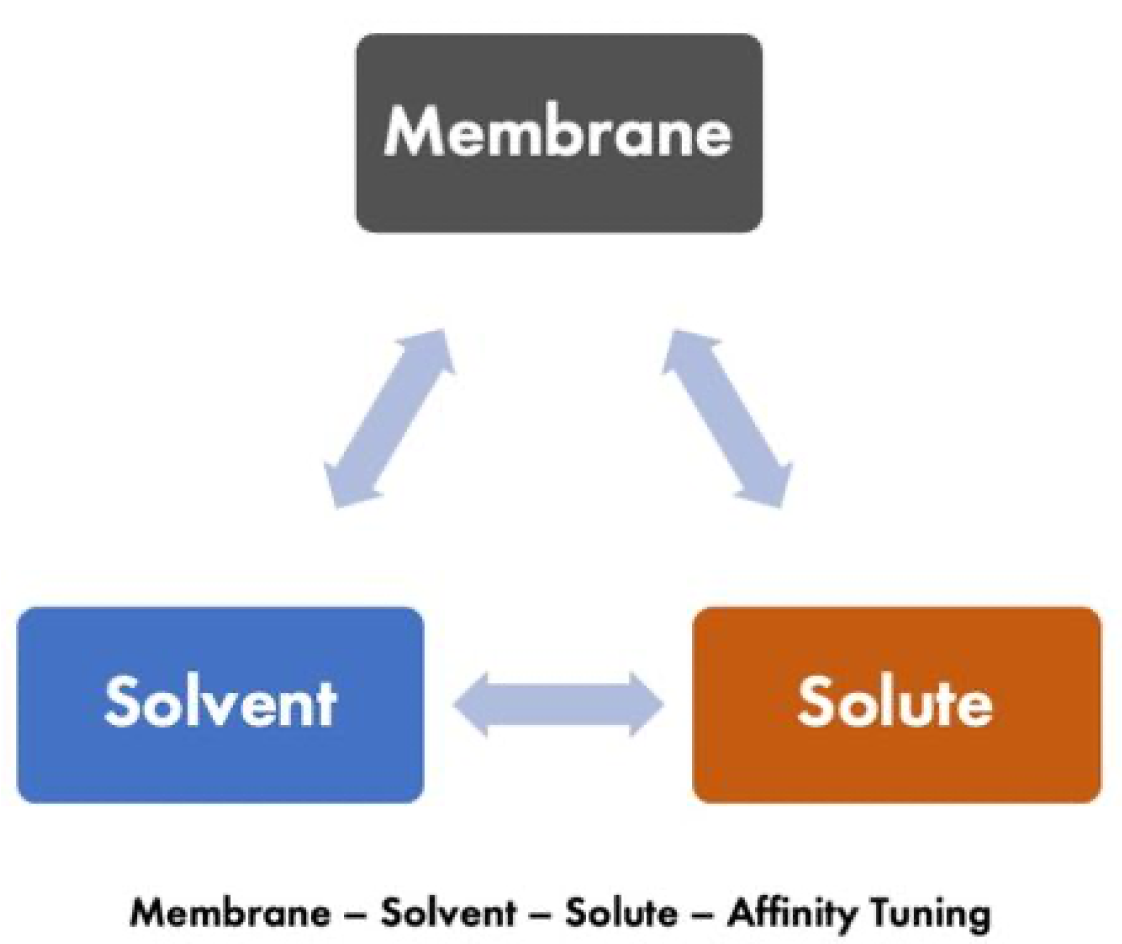

Tuning the membrane-solvent-solute affinity to the needs of the customers’ separation challenge leads to a performance increase. New separation processes become possible by membrane filtration and others become more efficient. A-membranes expand membrane filtration from a pure size-based separation process to an affinity-based separation process.

Strongly reduced fouling

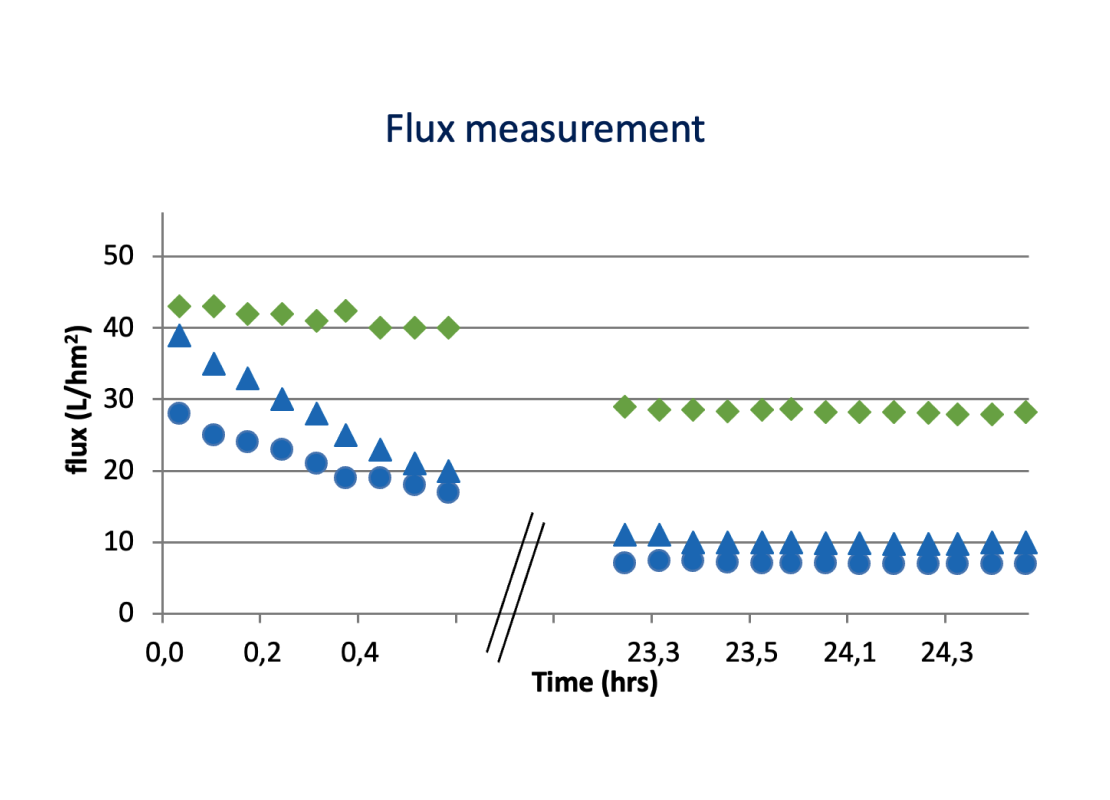

Olive oil production is very water intensive. The large amount of wastewater is difficult to treat. Membranes could be an energy- and cost-effective alternative for composting or biological treatment. Market membrane technology has a difficult time with the abundant fouling caused by the high concentrations of polyphenols present in this water.

Treatment of olive oil wastewater with nanofiltration A-membranes, in the framework of the European project CeraWater, has shown clear benefits.

The engineered anti-fouling affinity of the membranes resulted in 3x higher process fluxes combined with 5x higher COD retentions.

Compared to native, non-modified membranes. Moreover, a simple cleaning (forward flush with water), allowed to restore the pure water flux for 100%, confirming the high fouling resistance of the A-membranes.

A-membranes prevent so-called irreversible fouling!

Similar anti-fouling effects have been shown for nanofiltration A-membranes when treating other difficult waste waters as surface water (humic acid in combination with Ca2+ fouling, algae-fouling) and pulp and paper wastewater (lignin and (hemi)cellulose fouling).

In the context of a Dutch project (funded by ISPT) strongly reduced fouling was shown also for microfiltration A-membranes when treating a real oil/gas produced water. Currently, oil and gas production leads to about 7 barrels of wastewater for each barrel of oil/gas produced. This wastewater consists of a difficult to treat oil in water emulsion. Membranes, and particularly ceramic membranes, have proven to be one of the most efficient technologies, however, fouling is a serious issue. A grafted membrane, tailored for anti-fouling effects in this wastewater stream, has shown clear benefits: higher, more stable process fluxes and substantially higher retentions. Moreover, a one-step treatment in combination with a small amount of de-oiler, results in permeate qualities ready for direct discharge (dispersed oil discharge limit < 30 ppm).